This equipment has four knife shaft,can process high quality straight batten and pad bar material.

-1、The tool shaft has good stable performance, convenient adjustment, high speed, the speed is 6000 RPM, the processing surface is smooth, perfect, high precision.

-2、Each cutter shaft is equipped with large power, which can process four surfaces of pad bar material at one time.

-3、Compact structure, short spacing between tool shafts, high precision machining dimension.

-4、Working table plate plating hard collaterals, special wear-resistant, suitable for processing insulation parts requirements.

-5、The feeding system has strong power and adopts no chain universal transmission shaft, which is strong and stable. The workpiece is processed without carbonization and knife traces.

-6.The front and back of the table are equipped with two power rollers,

so that the feeding is more stable and smooth, to ensure the accuracy of the workpiece in the process of processing.

The main technical specifications:

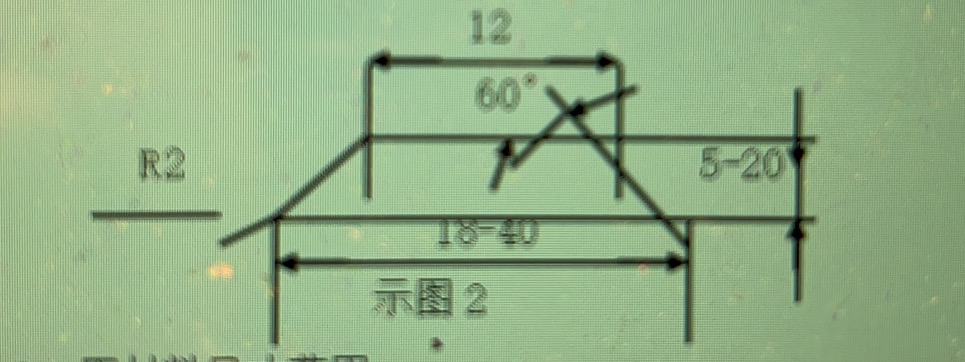

3-1, a single processing"T"type batten chamfer section size range:

3.2.2 Size range of raw materials;

Length L: 1000~3000mm

Thickness: 3~9mm

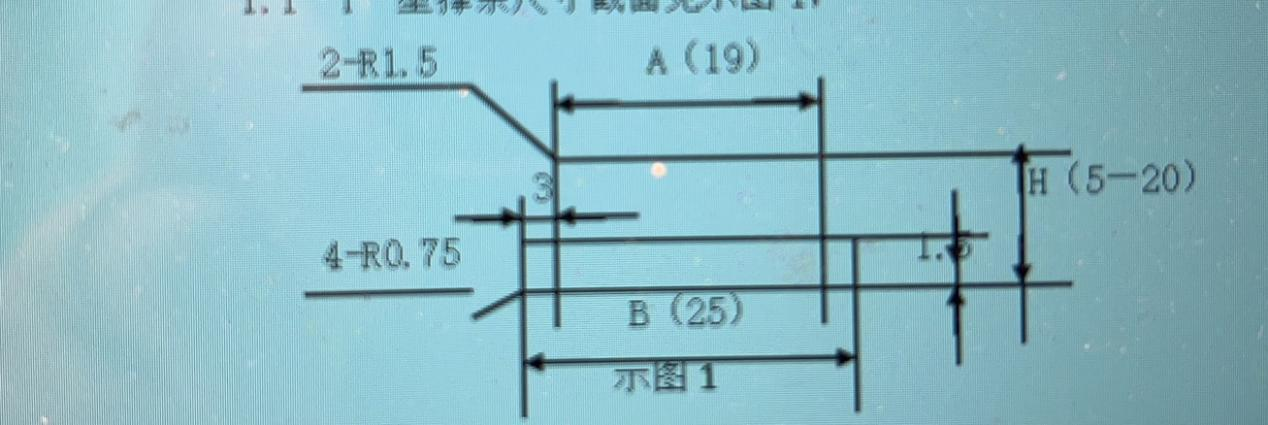

3-3Range of single rectangular brace for processing at a time:

Size range of raw materials; Length L; 600~3000mm

Width W : 10–70mm

Thickness T: 1.5–9mm

Only four R arcs can be processed when the thickness of straight brace is more than 15 mm.

Size range of cushion bar for first processing:

Length L; 600~3000mm

Width W : 10–70MM

Thickness T: 1.5–15 mm

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com